Guest Author: Sandra Wilson, Professor or Metal Design at DJCAD, University of Dundee.

Her research is funded by various UK research councils and her award winning jewellery and silversmithing is exhibited internationally.

Gold is now included on the European Chemical Society’s Endangered Elements list, as are silver and copper. Gold and copper are considered of “limited availability with a future risk to supply,” while silver is considered to have a “serious threat of extinction in the next 100 years”.

The Next Gold Rush Will Be In Landfills

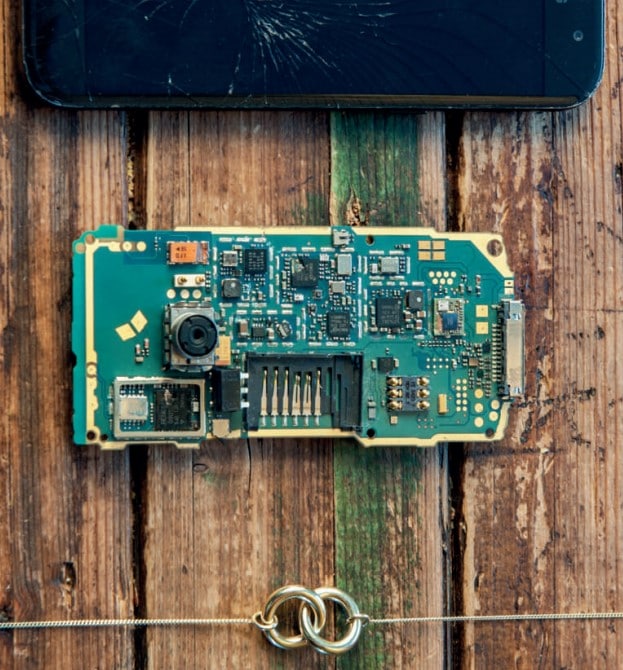

Of the gold that is mined today, around 52 percent is used by the jewelry and metal design industry, but an increasing proportion is used in the electronics industry on computer circuit boards, SIM cards, and smartphones for its non-corrosive qualities.

Today, about nine percent of the world’s supply of gold is tied up in electronics, and electronic waste is growing faster than any other solid waste stream.

Interestingly the yield from urban mining is considerably higher than from traditional ore mining processes. Whereas 1 ton of ore produces around 6 grams of gold, 1 ton of electronic waste, or e-waste, generates around 300 grams of gold. It only takes around 41 mobile phones to recover 1 gram of gold.

Generally as little as 20 percent of e-waste is recovered and recycled. In some countries this figure is even lower, for example in India it is as low as 1.5 percent.

For the first time in human history, we have started to consume gold; that is, we have started to lose gold in the discarded electronics deposited in landfills.

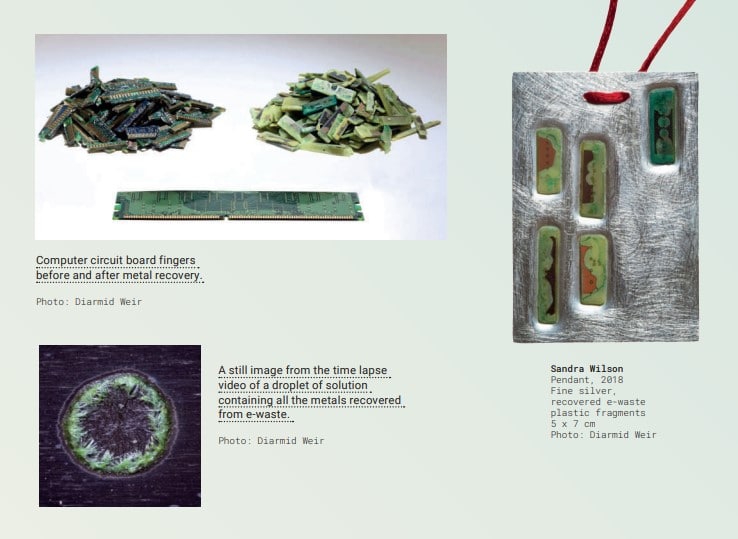

The most widely used and most cost-effective method for precious metal recovery is pyrometallurgy, in which the e-waste is separated, and parts containing precious metals are smelted.

E-waste is deposited into a high-temperature furnace and incinerated until only the precious metals remains.

Hydrometallurgy

Ancient alchemy was based on mystical and supernatural beliefs.

Modern alchemists are increasingly scientists and professionals from other discipines who recognise the vlaue of actively collaborating alongside jewelers.

Sandra Wilson: Gold Chloride Bowl, 2018 Britannnia silver, 10×7 cm

Photo: Diarmid Weir

In 2017, I was offered the opportunity to become the Artist in Residence working with Professor Jason Love’s team in the Chemistry Department at Edinburgh University.

Professor Love’s research group was working on a new chemical compound for recovering gold from e-waste using a hydrometallurgy process.

Creating jewelry from precious metals recovered from e-waste is clearly growing in popularity, but in some cases the process may be considered a marketing gimmic.

Hydrometallurgy is a greener and smaller-scale method of recovering precious metal from e-waste that uses aqueous solutions. It is set to rival the more established pyrometallurgy process in the future.

Biometallurgy

A third method of recovering precious metals from e-waste is biometallurgy. In this process, micro-organisms such as bacteria and fungus are used to recover the precious metals.

This unique low-carbon method is currently being developed in many chemistry laboratories around the world.

Biometallurgy, although a very slow process, may be the next big metal recovery technology.

A Circular Economy

Creating jewelry from precious metals recovered from e-waste is clearly growing in popularity, but in some cases the process may be considered a marketing gimmick.

Transporting and processing e-waste for pyrometallurgy extraction generates high levels of CO2 and can release toxic metals such as lead, arsenic, and mercury into the air, soil, and water.

The true future, once perfected, is smaller scale, less environmentally damaging hydrometallurgy and biometallurgy.

Olympic e-Waste Medals

The highest profile use of metal recovered from e-waste are the Olympic and Paralympic medals for the delayed Tokyo 2020 games.

The 5,000 medals were made from 78,985 tons of e-waste, and around 6.21 million donated used mobile phones.

An important way to halt the threat to the supply of gold from traditional ore mining in the next 100 years is to place a stronger emphasis on metal recovery from electronic waste.

Whether you are a jeweller or client, other blogs covering Ethical Jewellery, Workshop Sustainability, Sustainable Packaging and Sustainable Jewellery Creation.

I would like to thank Professor Sandra Wilson for this blog which is based on an article she wrote for Metalsmith Magazine.

If you are interested in following her work then she posts regularly on her website: www.sandrawilson.co.uk